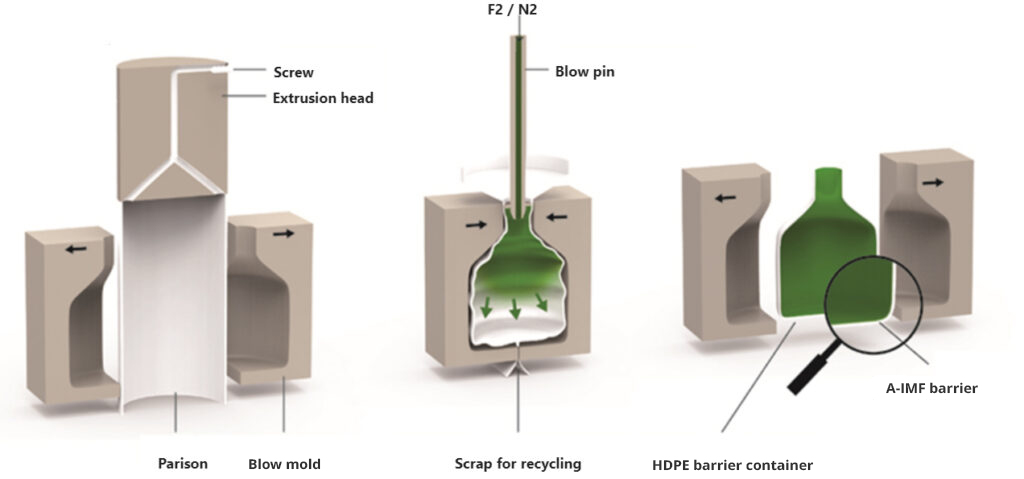

A-IMF barrier

Introduction of carefully controlled levels of fluorine during the HDPE extrusion blowing process to create an impermeable fluorinated barrier on the inner surface of the container

Click Here

Advanced In-Mold Fluorination

Mono-material barrier packaging

100% recyclable packaging

Lowest CO2 Footprint

Click Here

Advanced Barrier Packaging Technology for the protection, transportation and storage of your products.

Sustainable

Secure

Safe

Click Here

Product summary

Design and functionality meet in a high-quality, fully recyclable product. At a molecular level, our Advanced In-Mold Fluorination technology introduces a chemical barrier to the inner surface of a container within the HDPE blow molding process.

Dimensional, visual, and permeation consistency.

Combining excellent barrier properties with industry leading ease of recyclability, our Advanced In-Mold Fluorination results in Safe, Sustainable, and Secure containers for any industry.

Click Here

Previous slide

Next slide